TPR Rabber Yakarongedzwa Vertical Slurry Pump

Tspr rabara yakarongedzwaVertical slurry pombiSInowanikwa muzvikamu zvakasiyana-siyana kuti iwirirane zvakadzika madutu, kune yakadzika sumps yekudzora pombi, pombi yekunakisa inogona kuiswa pasi pezasi kuti uwedzere kudzika kwepombi kusvika pamamita maviri. Kupomba kunochengetwa kunyange kana iyo yepamusoro inlet isiri kunyudzwa, nokudaro ichigonesa iyo mwero wekudzikiswa pasi kusvika pasi pezasi kana pasi pe chero suction extension pombi. Nzvimbo dzakanyorova dzeTPR vertical Sump pombi inochinjika neiyo SP Series yakaoma simbi yakaremerwa inorema syump pump.

Dhizaina maficha

√ Kuve neGungano - Bhajeti, Shaft uye pekugara zvakarongedzwa nerupo kuti vadzivise matambudziko anoenderana nekushanda kwemashandisirwo ezvimedu nzvimbo dzekutanga.

Gungano rakaremara, rakarerutswa nokuvharwa nemwenje; iyo yekumusoro ndeye mafuta akacheneswa uye yakadzikira yakadzivirirwa neanonyanya kufadza. Iyo yekumusoro kana drive yekupedzisira ndeyekutanga chikamu cheyakafanana roller iripi iyo yakadzika kubereka ndeyekupedzisira inhetero mbiri roller ine preset magumo. Uku kuita kwakakura kwekuita kurongeka uye kusimba shaft inobvisa kudiwa kwekubereka kwakadzika kwekubereka.

√ Column gungano - rakanyatsogadzirwa kubva panyoro nyoro. Iyo TPR modhi ndeye elastomer yakafukidzwa.

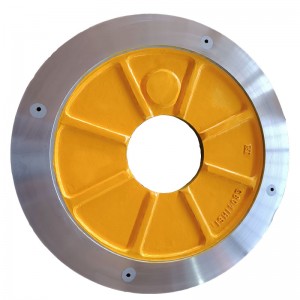

√ Casing - ine bhanhire rakareruka-pane kubatana pachigadziko chekamuri. Iyo yakagadzirwa kubva kune yakapfeka inodzivirira alloy yeTSP uye kubva ku yakaumbwa elastomer yeiyo tspr.

√ Impeller - Double Suction Imtellers (Pamusoro uye Pasi Pokupinda) Stace Low Axial Bearges uye iva nehuremu huni dzakakura kupfeka kupokana uye nekubata hombe solids. Pfeka zvakashata zvinopesana, polyurethane uye chakaumbwa elasmer vaneever vanopindirana. Iyo Impeller inogadziriswa pamwe chete mukati mekukanda panguva yekudyidzana nema shims pasi pekutakura makumbo ekubereka. Hapana kumwezve kugadzirisa kunokosha.

√ Upt Upthiner - kudonhedza-simbi mesh; Snap-pane elastomer kana polyurethane for tsp uye tpl pumps. Strivesers akakodzera muColumn vhura.

√ Yakadzika Drainer - yakakwenenzverwa simbi kana polyurethane yeTSP; yakaumbwa snap-pane elastomer yeTSPR.

√ Rasa PIPE - Metal yeTSP; Elastomer yakafukidzwa neTSPR. Zvikamu zvese zvakanyoroveswa zvizere zvine rukure zvakachengetedzwa.

√ Yakanyudzwa fani - hapana

√ Kugadziriswa - Iyo Yekunze Agitor TSPray yekubatanidza gadziriro inogona kuve yakagadzirirwa pombi seyisarudzo. Nenzira imwe cheteyo, mushambadzi wemagetsi anokodzera kuwanda kwekuwedzera kubva kune ziso remaziso.

√ Zvigadzirwa - Pumps zvinogona kugadzirwa mune zvinoshamisa uye zvinokanganisa zvinhu.

Tspr rabara yakarongedzwaVertical slurry pombis performer parameter

| Modhi | Max.power p (KW) | Zvakajeka Mvura Kuita | Impeller dia. (mm) | ||||

| Kugona Q | Musoro h (m) | Kumhanya n (R / min) | Max. Eff. (%) | ||||

| m3 / h | l / s | ||||||

| 40PV-TPR | 15 | 17.28-39.6 | 4.8-11 | 4-26 | 1000-2200 | 40 | 188 |

| 65QV-TPR | 30 | 22.5-105 | 6.25-29.15 | 5.5-30.5 | 700-1500 | 51 | 280 |

| 100RV-TPR | 75 | 64.8-285 | 18-79.2 | 7.5-36 | 600-1200 | 62 | 370 |

| 150SV-TPR | 110 | 108-479.16 | 30-133.1 | 8.5-40 | 500-1000 | 52 | 450 |

| 200sv-tpr | 110 | 189-891 | 152.5-247.5 | 6.5-37 | 400-850 | 64 | 520 |

| 250TV-TPR | 200 | 261-1089 | 72.5-302.5 | 7.5-33.5 | 400-750 | 60 | 575 |

| 300TV-TPR | 200 | 288-1267 | 80-352 | 6.5-33 | 350-700 | 50 | 610 |

TPR Rabber Yakarongedzwa Vertical Slurry Pumps Zvikumbiro

Iyo tsr uye sp Gravel, uye anenge ese tangi, gomba kana gomba-mu-pasi slurry kubata mamiriro ezvinhu.

ONA:

TPR Rubber Yakarongedzwa Vertical Slurry Pumps uye Spares inongochinjika neWarman® Spress SPR Rubber yakatsemuka midziyo uye spaares.

Th claple ved, yakatwasuka, centrifugal slurry pombi yezvinhu:

| Chinyorwa Cho | Tsananguro yezvinhu | Zvishandiso Zvikamu |

| A05 | 23% -30% cr White iron | Impeller, liners, plederller, plederller mhete, zvinhu zvinoridza bhokisi, pahuro |

| A07 | 14% -18% cr White Iron | Impeller, liners |

| A49 | 27% -29% cr low carbon White iron | Impeller, liners |

| A33 | 33% cr erosions & corrosion inopesana chena simbi | Impeller, liners |

| R55 | Rubber Natural | Impeller, liners |

| R33 | Rubber Natural | Impeller, liners |

| R26 | Rubber Natural | Impeller, liners |

| R08 | Rubber Natural | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey iron | Plame Plate, Dhavhara Plate, Dzivirira, Dziviriro Mhete, Bearing House, Base |

| D21 | Ductle iron | Carme ndiro, fukidza ndiro, inobereka imba, base |

| E05 | Carbon simbi | Shaft |

| C21 | Simbi isingazive, 4CC13 | Shaft Sleeve, lantern mhete, lantern airrior, mhete, gland bolt |

| C22 | Simbi isimbi, 304ss | Shaft Sleeve, lantern mhete, lantern airrior, mhete, gland bolt |

| C23 | Simbi isina tsvina, 316ss | Shaft Sleeve, lantern mhete, lantern airrior, mhete, gland bolt |

| S21 | Butyl Rubber | Kubatana mhete, zvisungo zvezvibatanidza |

| S01 | Epdm Rubber | Kubatana mhete, zvisungo zvezvibatanidza |

| S10 | Nitrile | Kubatana mhete, zvisungo zvezvibatanidza |

| S31 | Hypalon | Impeller, liners, deperller mhete, placeller, zvindori zvindori, zvakabatanidzwa zvisimbiso |

| S44 / K S42 | Neoprene | Impeller, liners, zvindori zvindori, zvisungo zvezvibatanidza |

| S50 | Viton | Kubatana mhete, zvisungo zvezvibatanidza |