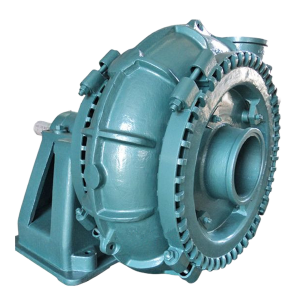

TSP / TPR Vertical Slurry Pump

TSP / TPR Vertical Slurry PumpYakagadzirirwa kuti zvikumbiro zvinoda kuvimbika zvakanyanya uye kusimba pane zvakajairika zvevatambi vertical pumps inogona kupa. Yakazara elasomer yakarongedzwa kana simbi yakaoma yakarongedzwa. Hapana fani yakanyungudutswa kana kurongedza. Yakakwira kugona kaviri kugadzirwa dhizaini. Yakagadzirirwa yakadzika yakadzika urefu uye kushungurudzika kusimuka kunowanikwa. Iyo TSP / TPR Vertical Sump pombi yakanakira kuremerwa kwekugara ichiramba kubata uye inokanganisa zvinwiwa uye slurries ichinyura mumabhuku kana makomba.

Dhizaina maficha

Pfeka zvishoma, kushoma corrosion

Zvinyorwa zvakanyoroveswa zvinowanikwa muzvikamu zvakasiyana uye zvevanyori vepamhepo zvinosarudza kusanganisa kwekunyepedzera kwekupfeka, kusanganisira izvo zvinodaira uye uko zvakakura zvekuita kana zvakakura zvimisikidzwa zvinosangana.

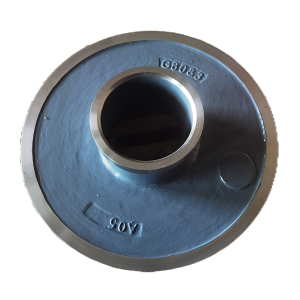

• Abrasion anodzivirira A05 Ultrachrome® Alloy.

• abrasion / corrosion-inodzivirira a49 hyperchrome® alloy.

• Corrosion-inodzivirira isina stain.

• Natural uye synthetic elastorers.

【Hapana akanyungudika achitadza kukundikana

Iyo Robbar Cantilever SHAFT inodzivirira kudiwa kweiyo yakadzika yakadzika fani - inowanzo soice yekutanga kutadza kutadza.

• Kurema kwebasa roller fani, pamusoro pekukwirisa.

• Hapana fani yakadzika.

• Labyrinth / Flinger Kuchengeta Dziviriro.

• yakaoma, yakakura dhayamita shaft.

Hapana Shaft Sealing Matambudziko

Iyo vertical cantilever dhizaini haidi kusimbisa Shaft.

√ Hapana priming inodiwa

Iyo yepamusoro uye yepasi inlet dhizaini yakakodzera "Snore" mamiriro.

√ njodzi isingakwanisi kuvharira

Iyo midziyo yakafukidzwa uye yakakura mapepa ekunyora anoderedza njodzi yekuvhara.

√ Zero Ancillary Mvura Mari

Iyo yakatwasuka Cantilever dhizaini isina gland kana yakanyungudika fani inodzivirira kudikanwa kwekudhura kweGland kana kubereka mvura inodonha.

TSP / TPRVertical slurry pombis performer parameter

| Modhi | Kufananidza simba p (KW) | Kugona Q (m3 / h) | Musoro h (m) | Kumhanya n (R / min) | Eff.] (%) | Impeller dia. (mm) | Max.particles (mm) | Uremu (kg) |

| 40pv-tsp (r) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV -T -T) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100RV-TSP (R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV -T -T) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200sv-tsp (r) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250TV -TV-R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV -TV (R) | 22-200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

TSP / TPRVertical slurry pombis application

Iyo TSP / TPR Verical Slurry Pumps inowanikwa mune yakasarudzika huwandu hwehukuru hwakakurumbira kuti huve hwakanyanya kupomerwa kupomerwa. Iyo tss / tppr sump mapapu arikuita kuti vazivikanwe uye kushanda kwavo pasi rese mu: kugadzirira kwemakemikari, jecha uye rimwe tangi, gomba kana gomba. Iyo tss / tsr pombi dhizaini ine mesimbi yakaoma (tsp) kana elasomer yakafukidzwa

*

Th claple ved, yakatwasuka, centrifugal slurry pombi yezvinhu:

| Chinyorwa Cho | Tsananguro yezvinhu | Zvishandiso Zvikamu |

| A05 | 23% -30% cr White iron | Impeller, liners, plederller, plederller mhete, zvinhu zvinoridza bhokisi, pahuro |

| A07 | 14% -18% cr White Iron | Impeller, liners |

| A49 | 27% -29% cr low carbon White iron | Impeller, liners |

| A33 | 33% cr erosions & corrosion inopesana chena simbi | Impeller, liners |

| R55 | Rubber Natural | Impeller, liners |

| R33 | Rubber Natural | Impeller, liners |

| R26 | Rubber Natural | Impeller, liners |

| R08 | Rubber Natural | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey iron | Plame Plate, Dhavhara Plate, Dzivirira, Dziviriro Mhete, Bearing House, Base |

| D21 | Ductle iron | Carme ndiro, fukidza ndiro, inobereka imba, base |

| E05 | Carbon simbi | Shaft |

| C21 | Simbi isingazive, 4CC13 | Shaft Sleeve, lantern mhete, lantern airrior, mhete, gland bolt |

| C22 | Simbi isimbi, 304ss | Shaft Sleeve, lantern mhete, lantern airrior, mhete, gland bolt |

| C23 | Simbi isina tsvina, 316ss | Shaft Sleeve, lantern mhete, lantern airrior, mhete, gland bolt |

| S21 | Butyl Rubber | Kubatana mhete, zvisungo zvezvibatanidza |

| S01 | Epdm Rubber | Kubatana mhete, zvisungo zvezvibatanidza |

| S10 | Nitrile | Kubatana mhete, zvisungo zvezvibatanidza |

| S31 | Hypalon | Impeller, liners, deperller mhete, placeller, zvindori zvindori, zvakabatanidzwa zvisimbiso |

| S44 / K S42 | Neoprene | Impeller, liners, zvindori zvindori, zvisungo zvezvibatanidza |

| S50 | Viton | Kubatana mhete, zvisungo zvezvibatanidza |